Recently, the cooperation agreement on mineral resources between the United States and Ukraine has become a focus, especially the rare earth elements involved, which have drawn global attention and highlighted the strategic position of rare earths in global technological competition and the industrial chain. So, what exactly is "rare earth" and why is it so important?

Rare earth is not "earth" and has significant differences in chemical properties from ordinary "earth" (mainly composed of silicates, etc.). The name of rare earth elements originated from the research discoveries in the late 18th century to the 19th century. At that time, these elements were extracted from uncommon minerals and were relatively scarce in nature, thus being called "rare earth" (Rare Earth). Although we now know that some of these rare earth elements are not truly rare (the abundance of certain rare earth elements in the Earth's crust is much higher than that of common metals such as gold and silver), at that time, the discovery and separation techniques were very limited, leading to this naming.

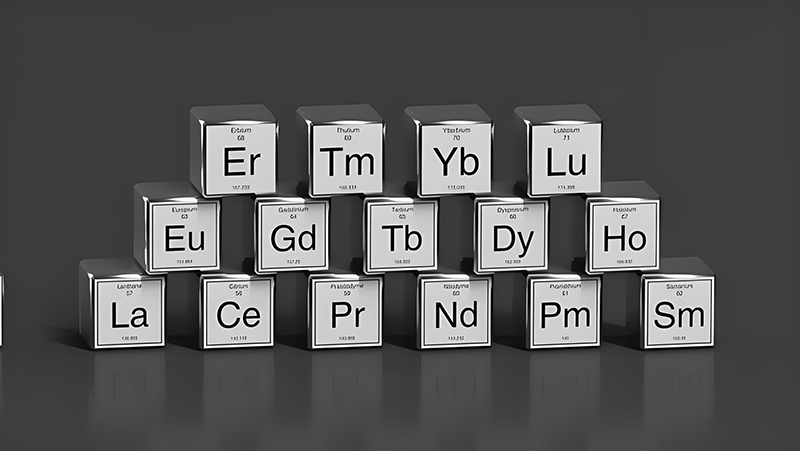

In fact, rare earth is a collective term for 17 metallic elements including the 15 lanthanide elements and scandium and yttrium. Due to their unique electron layer structure, rare earth elements possess unique physical and chemical properties and hold a crucial strategic position in modern economy and defense technology. They are core materials in high-tech industries, driving global technological innovation and industrial upgrading, and are also indispensable key materials in advanced weapon systems, radars, missiles, satellites, and stealth technology, directly related to a country's military superiority and national defense security. Therefore, rare earth not only has resource attributes but also technical and strategic attributes. Ensuring the stability of the rare earth supply chain has become a top priority in the economic and defense strategies of various countries.

Rare earth elements play an irreplaceable role in magnetic materials, catalysts, optical materials, neutron-absorbing materials, hydrogen storage materials, aerospace alloy materials, etc.

Magnetic materials are one of the main application fields of rare earth elements, accounting for about 60% of the total rare earth. Among them, rare earth permanent magnetic materials account for the vast majority. In 2024, China's production of rare earth permanent magnetic materials has accounted for about 90% of the global total. In the production of medium and low-end neodymium-iron-boron magnets, light rare earth elements such as neodymium (Nd) and praseodymium (Pr) are mainly used; while in high-end neodymium-iron-boron magnets, terbium (Tb) and dysprosium (Dy) and other heavy rare earth elements must be added to further enhance their high-temperature stability and anti-demagnetization ability. Neodymium-iron-boron magnets, due to their excellent performance, are indispensable in many modern technology and industrial fields such as electric vehicle drive motors, wind turbines, and consumer electronics, effectively promoting the rapid development of clean energy, information technology, and high-end manufacturing. Samarium cobalt magnets are also important members of rare earth magnetic materials, with high magnetic energy product, excellent high-temperature resistance and corrosion resistance, and become the only choice in some extreme environments. For example, in high-temperature scenarios such as aerospace engines and oil drilling equipment, samarium cobalt magnets can work stably; in strongly corrosive environments such as the ocean and chemical equipment, their corrosion resistance makes them irreplaceable materials; in high-precision measurement instruments and other scenarios with extremely high requirements for magnetic field stability, samarium cobalt magnets also play a key role. In addition, terbium-dysprosium-iron as a high-performance magnetostrictive material, with high energy conversion efficiency and fast response characteristics, has become a core component in sonar systems, ultrasonic transducers, and precision mechanical positioning systems, holding an irreplaceable position. Moreover, rare earth cryogenic magnetic refrigeration technology, as the only refrigeration method not relying on helium-3 at present, has significant strategic significance and helps reduce dependence on imported helium-3 resources. It shows broad application prospects in frontier technologies such as high-energy physics, quantum computing, and deep space exploration.

In the field of catalysis, the consumption of rare earths accounts for as high as 20% - 25%, making it the second largest application direction of rare earths globally after permanent magnetic materials. Its core value lies in the unique 4f electron layer structure of rare earth elements, which can significantly enhance the efficiency and environmental performance of catalytic reactions. In the field of petroleum cracking, lanthanum (La) and cerium (Ce) are used as auxiliary catalysts in petroleum cracking catalysts, which can improve catalytic activity, enhance thermal stability, extend catalyst lifespan, and improve product selectivity. At the same time, it helps reduce the emission of harmful gases such as SOx/NOx during the refining process, reducing environmental pollution, and is a key element of petroleum cracking catalysts. In the field of vehicle exhaust purification, cerium-based oxygen storage materials (CeO2-ZrO2) utilize the dynamic oxygen storage-release characteristics to increase the CO/HC oxidation efficiency and NOx reduction rate of the three-way catalysts to over 98% and 90% respectively, making them a key material to meet the standards of Euro VI and China VI emissions. In addition, rare earths play an indispensable role in emerging environmental protection fields such as SCR denitration catalysts and solid oxide fuel cells, fully demonstrating the strategic value of rare earths in the green upgrade of traditional industries and the breakthrough of new energy technologies.

Scan to wechat :