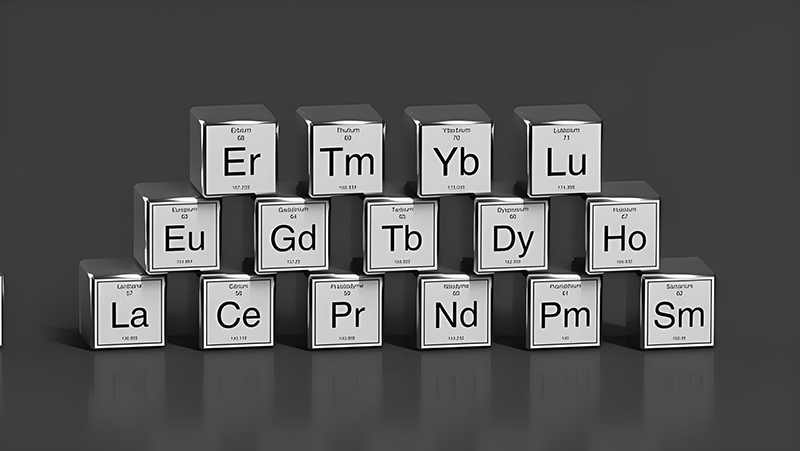

In the field of optical material applications, the rare earth elements La, Nd, Yttrium (Yb), and Erbium (Er) play a crucial role in high-performance optical devices. They can significantly enhance the refractive index and dispersion properties of camera lenses, telescopes, and other precision optical glasses, thereby optimizing imaging quality. Moreover, rare earth elements are indispensable in solid-state lasers, providing specific wavelength laser output. The strict control requirements for key impurity contents in rare earth raw materials for solid-state lasers are typically at the ppm (parts per million) or even ppb (parts per billion) level. Rare earth elements are also key dopants in semiconductor materials, playing a significant role in improving their electrical and optical properties. For example, doping with rare earth elements in photodetectors can enhance the sensitivity of the material to specific wavelengths, thereby improving the detection efficiency. In fiber amplifiers, rare earth elements (such as Er) can amplify light signals through stimulated emission, and are widely used in long-distance fiber communication systems. Additionally, rare earth elements such as Europium (Eu), Terbium (Tb), and Cerium (Ce) have unique applications in the field of luminescent materials. They can emit specific wavelengths of light, being the core materials for manufacturing fluorescent powders in energy-saving lamps, LEDs, and display screens.

In the field of neutron-absorbing materials, Gadolinium (Gd) and Samarium (Sm) have an irreplaceable and significant role in the nuclear energy sector, especially in control rods of nuclear reactors. Control rods, as the core component for regulating the rate of nuclear fission reactions, precisely control the reactor power output by absorbing neutrons, ensuring stable operation; in emergency situations, control rods can be quickly inserted into the reactor core to terminate the chain reaction and prevent reactor runaway, thereby providing important security guarantees for nuclear power plants. Moreover, the use of Gadolinium and Samarium reduces reliance on traditional control rod materials (such as cadmium and boron), not only improving the reactor's performance but also optimizing its design, and has become an indispensable functional material in modern nuclear reactors.

Rare earth hydrogen storage alloys are the negative electrode materials commonly used in nickel-hydrogen batteries. Rare earth elements can form stable hydrides with hydrogen, thereby increasing hydrogen storage capacity, reducing reaction activation energy, making the battery more efficient during charging and discharging, improving the kinetics of hydrogen absorption and release, enabling rapid charging and discharging, and inhibiting the pulverization and degradation of the alloy during repeated hydrogen absorption and release, extending the battery life. Rare earth elements (such as Yttrium, Gadolinium, and Samarium) are also indispensable in the electrolytes of solid oxide fuel cells, significantly enhancing oxygen ion conductivity and thermal stability, being the key to their efficient operation. For example, Gd2O3 or Sm2O3 doped CeO2 exhibits higher oxygen ion conductivity in the medium-temperature range (500°C - 700°C); Yttrium doping introduces oxygen vacancies in the zirconium lattice, promoting oxygen ion migration, significantly improving oxygen ion (O²-) conductivity at high temperatures (800°C - 1000°C).

Rare earth elements are not only widely used in functional materials but are also indispensable key materials in structural materials. Their unique physical and chemical properties can significantly enhance the performance of alloys, meeting the stringent requirements of aerospace for materials with high strength, high temperature resistance, and corrosion resistance. By adding rare earth elements, the grain structure of alloys can be refined, strength, toughness, fatigue resistance, and corrosion resistance can be improved, thereby extending the service life of components. In particular, rare earth elements can improve the high-temperature stability and creep resistance of high-temperature alloys, making them suitable for extreme environments such as the hot-end components of aircraft engines. Moreover, in lightweight design, rare earth magnesium alloys, due to their low density, high specific strength, and heat resistance, are ideal materials for manufacturing satellite and spacecraft structural components, providing important support for modern aerospace technology development. Rare earth elements hold significant importance in traditional industries and high-tech fields, and also play a crucial role in energy transition, information technology development, and frontier scientific research. With the continuous growth of global demand for clean energy, intelligent technologies, and high-end manufacturing, the strategic value of rare earth materials will become increasingly prominent, becoming an important pillar for enhancing a country's technological competitiveness and ensuring economic security. Of course, the challenges of rare earth lie in the technical complexity and environmental protection requirements of its mining, purification, and processing processes, as well as the economic and political issues arising therefrom. With technological progress and the improvement of environmental awareness, these problems are gradually being resolved, but they remain key factors restricting the development of the rare earth industry.

Scan to wechat :